The Greatest Guide To Powder Coating In Santa Clarita

Wiki Article

Santa Clarita Powder Coating Shop - The Facts

Powder layers have a significant benefit because the overspray can be reused. However, if numerous colors are being sprayed in a single spray cubicle, this might restrict the ability to recycle the overspray. Advantages over other finish procedures [modify] Powder finishings contain no solvents as well as launch little or no quantity of unpredictable organic substances (VOC) into the ambience.

Some Of Powder Coating In Santa Clarita

View Powder Coating Plus, Inc. Santa Clarita in a full screen map

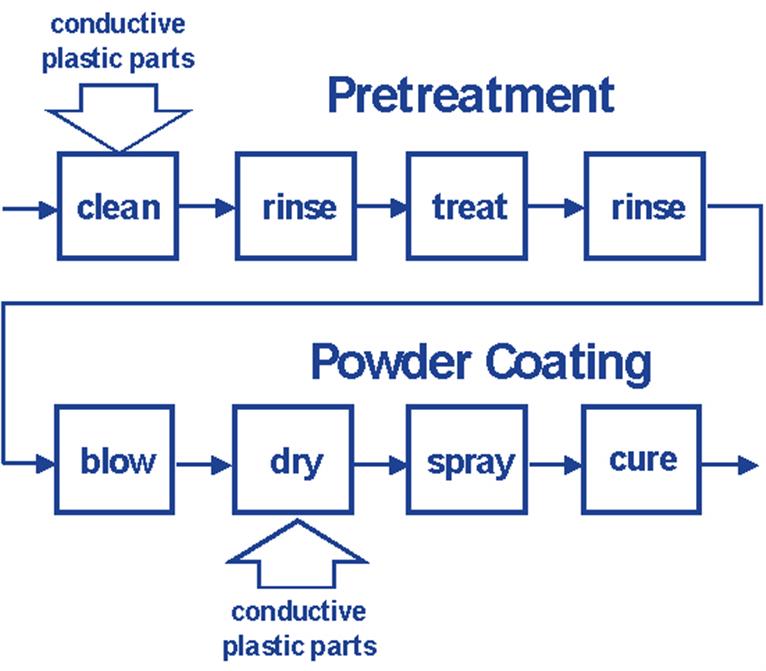

UV-cured powder will certainly thaw in 60 to 120 seconds when reaching a temperature level 110 C and 130 C. Once the melted covering remains in this temperature home window it is quickly healed when subjected to UV light. One of the most usual polymers made use of are: polyester, polyurethane, polyester-epoxy (called hybrid), straight epoxy (fusion bound epoxy) and polymers [] Manufacturing [edit] The polymer granules are blended with hardener, pigments as well as other powder components in an industrial mixer, such as a turbomixer The blend is warmed in an extruder The extruded blend is rolled level, cooled down and also burglarized tiny chips The chips are grated and sieved to make a great powder Technique [modify] The powder coating procedure includes three basic actions: component prep work or the pre-treatment, the powder application, as well as treating.

is important before the powder coating procedure. It can be done by a range of chemical and also mechanical methods. The selection of the approach depends on the dimension and the product of the part to be powder coated, the kind of contaminations to be removed as well as the efficiency need of the finished item.

Santa Clarita Powder Coating Can Be Fun For Everyone

Cast steel shot or steel grit is utilized to clean and also prepare the surface prior to covering. This approach of prep work is very effective on steel components such as I-beams, angles, pipes, tubes and also big fabricated items.The sort of nozzle made use of will depend upon the form of the workpiece to be repainted and the consistency of the paint. The object is after that heated, as well as the powder melts right into a consistent film, as well as is after that cooled to develop a tough covering. It is likewise usual to warm the steel initially and afterwards spray the powder onto the hot substrate - santa clarita powder coating shop.

Excitement About Santa Clarita Powder Coating Shop

In this case, the powder picks up a positive fee while massaging along the wall surface of a Teflon tube inside the barrel of the gun. These billed powder particles after that adhere to the based substratum.Additional home heating is normally called for to complete curing the coating. This technique is usually made use of when the wanted density of coating is to exceed 300 micrometres. This is how most dishwasher shelfs are layered. Electrostatic fluidized bed finishing [modify] Electrostatic fluidized bed application makes use of the exact same fluidizing method as the standard fluidized bed dip check process but with a lot more powder depth in the bed.

Santa Clarita Powder Coating - An Overview

Charged bits of powder move up and develop a cloud of charged powder above the fluid bed. When a based component is passed via the charged cloud the fragments will certainly be attracted to its surface. The parts are not preheated as they are for the traditional fluidized bed dip procedure.

What Does Powder Coating In Santa Clarita Do?

HAA polyesters tend to overbake yellow more so than TGIC polyesters. The healing timetable could differ according to the manufacturer's specs. The application of energy to the item to be treated can be accomplished by convection cure ovens, infrared treatment ovens, or by laser healing process. The latter demonstrates considerable reduction of healing time.To repaint or to powder coat? Why pick powder covering finishes over paint? Powder covering, on the other hand, is an extra innovative strategy.

Getting My Powder Coating Santa Clarita To Work

Powder finish is applied as completely dry powder through an electrostatic procedure, after that cured with heat. The powder coating finishes are not just strong yet adaptable.There are two kinds of powder finishing, thermosets and also thermoplastics. santa clarita powder coating. Thermoplastic powder layer surfaces end up being liquid and also really soft when heated up. This removes chemical bonding. This process makes the powder covering both relatively easy to fix as well as multiple-use. Polycarbonate layers tend to be thicker, as well as thus a lot more resilient contrasted to thermoset coatings. Therefore, they can be used for a variety of points from steel, automobile parts, and also fridges.

How Santa Clarita Powder Coating can Save You Time, Stress, and Money.

Prep work is the first step of the procedure and perhaps the most essential one. This action determines just how well the powder layer sticks to the steel surface area, as well as there are various alternatives for cleansing and prepping the surface area.Report this wiki page